Kanban Racks

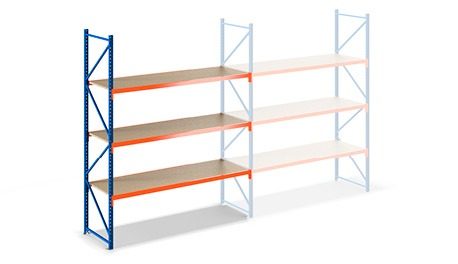

Inclined shelves are often used for storage and distribution of small parts. The advantages of slanted shelves based on a storage rack are obvious. The warehouse employee immediately sees the stock of the goods, loose storage items can slide directly to the front and thus storage space is optimally utilized.

Kanban Racks Top seller

Inclined shelf type SR2000

- Shelf height 2m - 4m

- Ideal for storage of open fronted storage bins, shepherd boxes & small parts.

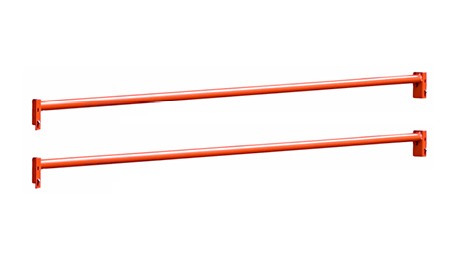

- Cross beams are the load carriers of an inclined shelf. Individually height adjustable in 5cm increments. Available in 110cm and 220cm

- Inclined shelves with round crossbars to protect against falling down

- Wooden shelves for optimal storage of dry products, such as cartons or storage boxes

- Round traverses for protection against falling storage goods

- Also available as mobile inclined shelf unit

Easy to assemble

Easy to assemble Best price

Best price All parts included

All parts included

Download area

Overview uprights storage rack LR2000

Painted uprights

- variable heights

- Bay load: 1.500kg

- complete upright incl. braces and foot parts

Variants

Stationary or mobile

With the height-adjustable base with castor, your mobile inclined shelf can be adjusted in height by up to 40cm. This results in individually adjustable heights of 85cm - 254cm, depending on the type and selected basic size.

Bay, shelf and point load

Bay load stationary max. 1500 kg

Bay load mobile max. 500 kg

- Total load capacity between 2 shelf uprights

Technical information

Floor anchoring foot plate

The floor anchoring is done by using bolt anchors M8x55

- Drill holes: 8mm Ø, 80mm deep

- Blow out holes

- Hammer the bolt anchor into the drilled hole

- Tighten the nut with an open-end wrench or similar

If the height of the top shelf is less than 5 times the shelf depth, the shelf does not need to be fixed or secured against tipping.

Please note: The bolt anchors must be fastened professionally.

Our in-house assembly team will be happy to professionally assemble your shelves.

Modular construction

Axle dimensions

- Axle dimension describes the width of a shelf bay as well as the distance between two uprights

- We offer axle dimensions in the widths 110cm and 220cm

- The dimensions of the axes can be freely combined with each other.

- Configure your storage rack individually with your desired bay lengths. Due to the modular construction the racks can be extended at any time.

Technical Information

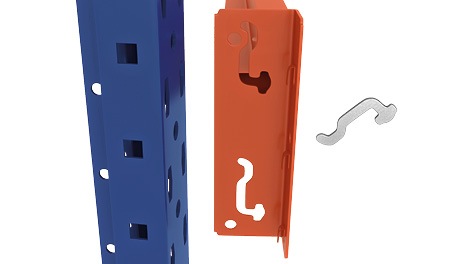

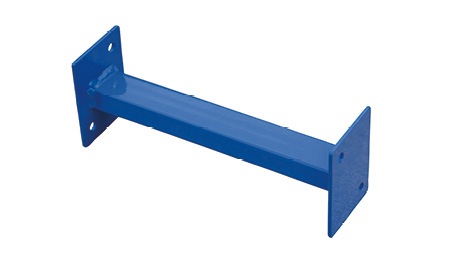

Securing the cross beams

Required individual parts: Pre-assembled shelf upright, truss, securing pin.

Set up the pre-assembled uprights and hook the crossbars into the upright profile on both sides at the desired height. Insert the locking pins into the hole provided in the truss.

The trusses are hung in a grid of 50mm.

Please note: Mount the last truss at least 50cm before the end of the upright!

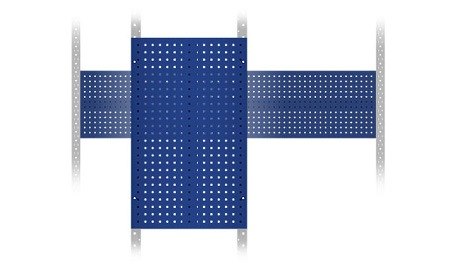

Spacers

Wall mounting / Connecting

Color: Top shelf blue (corresponds to RAL 5010).

For rack heights up to 2.5m we recommend the use of 2 spacers.

From a height of 3m we recommend the use of 3 spacers.

All assembly material is included in the price and scope of delivery.

Operational safety / regulation - DIN EN 15635, DGUV 108-007

Collision protection for racking systems

Collision protection to prevent possible damage to the rack upright.

Corner areas must be equipped with a collision protection according to DIN EN 15365 & DGUV 108-007 in case of forklift traffic.

Our collision protection is tested and certified according to DGUV 108-007 (formerly BGR234).

Each collision protection is delivered including four bolt anchors M12x100mm for floor fixing.

Examples of possible configurations

Accessories - suitable for SR2000

Optimal storage of small parts in sloping shelf racks

Inclined shelves are often used for storage and distribution of small parts. The advantages of the slanted shelves on the basis of a storage rack are obvious. The warehouse employee can immediately see the stock of the goods, loose stock items can slide through directly to the front and thus storage space is optimally utilized.

The principle of the inclined shelf comes from the Japanese process optimization method Kanban. Here, goods that have been removed are directly replenished using the fetch principle. It is therefore not surprising that the inclined shelf is also known as Kanban shelf. Removed goods can be refilled directly from the back and, thanks to the 20° angle of the shelf, automatically slide forward, where the securing round tube holder keeps the goods in place and always in the same place ready for removal. In this way, the parts that have been stored the longest can be conveniently removed first and there is no need for laborious rearrangement of the goods.

Very small parts, such as screws, are safely stored in open fronted storage bins or easily visible boxes. TOPREGAL offers suitable sloping shelf accessories and open fronted storage bins in various sizes to match the stored goods or in a more economical set with several foldable open fronted storage bins. There is also a practical solution for labeling the stored goods in the sloping shelf - especially in the higher areas that are not easily visible to the naked eye: the rewritable magnetic tape.

It doesn't matter whether the inclined shelf is placed against a wall on one side or as a double inclined shelf in the middle of the warehouse, if it is to be extended later, this is possible at any time thanks to the simple modular design. If you like it very flexible, you can also buy it in the variant mobile inclined shelf or retrofit it later with a set of wheels. For this, it is best to contact us briefly.

Easy to assemble

Easy to assemble